Fluid Coupling

Chinese liquid coupler manufacturer, specializing in production for more than 20 years.

Automatic Transmission

Prior to the introduction of fluid coupling, all vehicles used manual transmissions. Manual transmissions require drivers to operate the clutch which acts as a connection to the engine as well as transmission. Without the clutch in a manual car, the vehicle could stop when parked.

The invention of the coupling fluid has eliminated the necessity for clutches. It is the main source for the necessary torque conversion for the car to switch gears in a controlled manner. Every vehicle that is autonomous currently on the road is made up of fluid coupling.

Semi-automatic Transmission

Fluid couplings aren’t restricted just to vehicles. Fluid couplings also offer significant advantages when it comes to rail transport.

In the UK diesel locomotives use an autonomous power transmission system. The power transmission system uses fluid couplings to automatically shift gears as the locomotive is moving.

Other Sources

While they are less than 100 years old Fluid couplings have changed the way that locomotives and automobiles function. The automotive industry operates on its foundations and wouldn’t be the same without them.

About

What Is Fluid Coupling

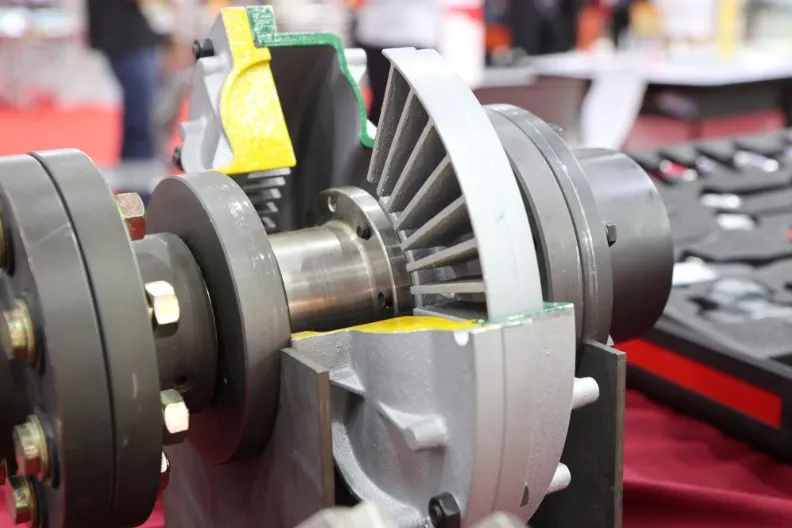

A fluid coupling is a mechanical device used to transmit rotational power between two shafts. It utilizes a hydraulic fluid to transfer torque from a driving shaft to a driven shaft. The fluid coupling consists of three main components: the impeller, the runner, and the fluid itself.

The impeller is typically connected to the driving shaft and is responsible for generating fluid flow within the coupling. It consists of radial blades or vanes that push and accelerate the hydraulic fluid.

The runner, connected to the driven shaft, is a set of radial blades mounted on a drum-like structure. It receives the fluid flow from the impeller and converts the hydraulic energy into mechanical energy to drive the driven shaft.

The fluid, often a specialized hydraulic oil, fills the space between the impeller and the runner. It serves as the medium for torque transmission. The fluid is accelerated by the impeller and then directed toward the runner. The fluid flow creates hydraulic forces that transfer torque from the impeller to the runner, resulting in the rotation of the driven shaft.

Features

Special features for fluid couplings include:

- delay chambers

- dynamic refill

- adjustable drain nozzles

- centrifugal valves

- multiple operating circuits

The retard chamber is utilized for providing more relief to the motor when it is starting up. They also facilitate better efficiency and a smoother start when operating normally. A turbo coupling that has a delay chamber and dynamic refill does an excellent job of relieving the drive motor whenever the motor’s speed is reduced. Typically mineral oil or water is the primary working fluid. Fluid couplings that have different circuits are also offered.

Advantages of Fluid Coupling

Smooth Power Transmission

Fluid couplings provide smooth and gradual torque transfer between the driving and driven shafts. This helps in reducing shock loads and vibrations, resulting in smoother operation and extended equipment lifespan.

Overload Protection

Fluid couplings act as a protective mechanism by allowing limited slippage during sudden load changes or overload conditions. This protects the connected machinery from damage by absorbing the excess torque and preventing sudden acceleration.

Torque Amplification

Fluid couplings can amplify torque during startup or when there is a significant speed difference between the driving and driven shafts. This is particularly useful in applications where high starting torque is required, such as conveyor systems or heavy machinery.

Vibration Damping

The fluid within the coupling helps to dampen torsional vibrations and resonance frequencies, thereby reducing stress on the connected equipment and minimizing the risk of fatigue failure.

Load Sharing

Fluid couplings facilitate load sharing between parallel shafts or multiple driven units. When multiple machines are connected to a common shaft, the fluid coupling helps in distributing the load evenly among them, preventing excessive strain on any individual unit.

Inherent Slip Control

Fluid couplings have a certain amount of slip, which allows for speed variation between the driving and driven shafts. This slip can help in compensating for speed differences caused by variations in load or during deceleration, providing better control over the system.

Maintenance-Free Operation

Fluid couplings do not have any mechanical wear components like gears or friction clutches. This results in maintenance-free operation and reduces the need for frequent lubrication or adjustment.

High Efficiency

Modern fluid couplings are designed for high efficiency, with minimal power losses during operation. This helps in reducing energy consumption and improving overall system efficiency.

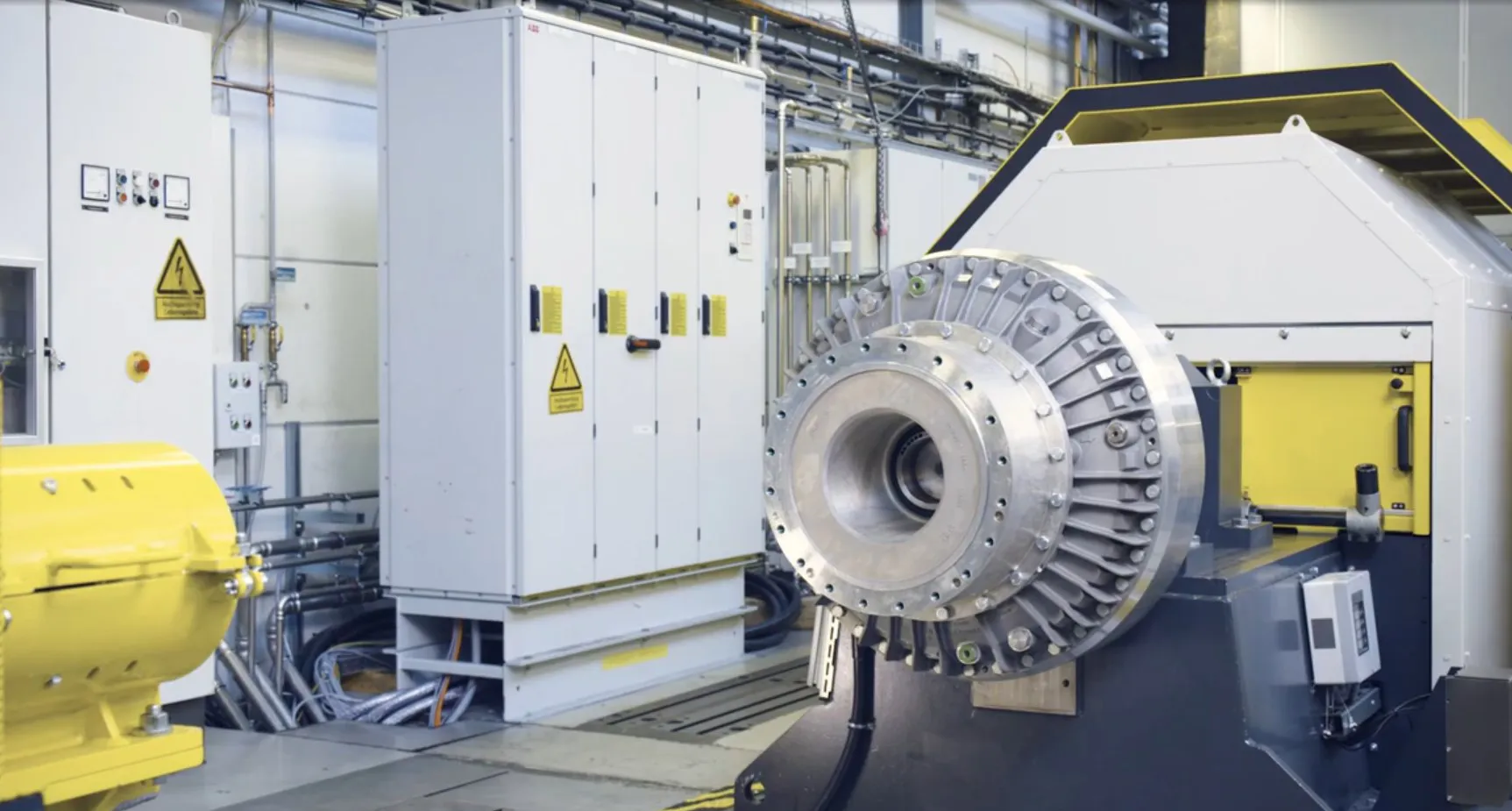

Fluid Coupling for Sale

As a fluid coupling manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

How Fluid Coupling Works

A fluid coupling works based on the principle of hydraulic fluid flow and fluid friction. Here’s a step-by-step explanation of how a fluid coupling operates:

Initial Conditions

The fluid coupling is filled with a hydraulic fluid, typically oil. The driving shaft, connected to the impeller, starts rotating, while the driven shaft, connected to the runner, remains stationary.

Impeller Rotation

As the driving shaft rotates, it spins the impeller inside the fluid coupling. The impeller consists of curved blades or vanes that push and accelerate the hydraulic fluid radially outward.

Fluid Flow

The centrifugal force created by the rotating impeller propels the hydraulic fluid toward the outer edges of the fluid coupling. This generates a circulating flow pattern within the coupling.

Fluid Friction and Torque Transfer

As the fluid flows from the impeller to the runner, it encounters the stationary blades of the runner. The fluid undergoes a change in direction, creating fluid friction.

Torque Transmission

The fluid friction between the impeller and the runner causes a transfer of torque from the driving shaft to the driven shaft. The torque is transmitted through the hydraulic fluid, allowing the driven shaft to start rotating.

Slippage

In normal operating conditions, there is a certain amount of slippage between the impeller and the runner. This slippage allows for smooth torque transmission, absorbs shocks, and provides a degree of overload protection. The slippage occurs due to the difference in the speeds of the impeller and the runner.

Speed Equalization

As the driven shaft accelerates, its speed approaches that of the driving shaft. As the speed difference decreases, the slippage reduces, resulting in a more efficient transfer of power.

For more information on liquid couplers, please contact us.

Store Hours

Monday–Friday: 6am – 5pm

Saturday: 8am – 4pm